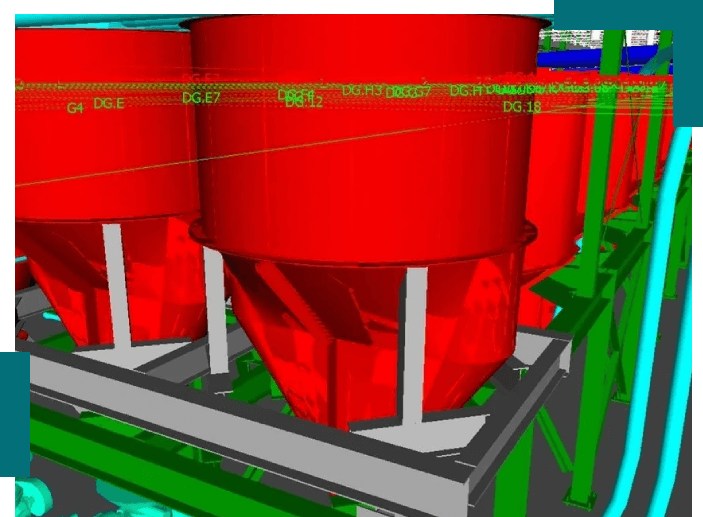

Oscillating Plate Hopper

We can retrofit most hoppers with oscillating plates that decrease frictional forces in the direction of flow, reducing energy input and maximizing material discharge without hangups. The Oscillating Plate Hopper works with materials that are too sticky or cohesive to discharge in typical hoppers.

The Oscillating Plate Hopper significantly enhances material flow, especially for challenging substances.

By strategically placing oscillating plates inside a hopper, it reduces arching tendencies by half compared to standard hoppers. This enables efficient discharge through outlets half the normal size. The system promotes plug flow or a first-in / first-out pattern, ensuring reliable, hang-up-free operation for materials like water-soluble salts, powdered resins, fly ash, corn gluten, and spent vanilla beans, without the need for steep hopper angles, prodding, vibration, or hammering.

Typical Retrofit Applications

- Feeding an educator's throat consistently, without hangups

- Retrofitting existing hopper shapes to eliminate ratholing

- Retrofitting existing conical hoppers to eliminate

- Segregation flow patterns by providing flow at the walls

- Providing consistent density feed to volumetric or gravimetric feeders

Features

- Oscillating plates that retrofit most hopper configurations

- Oscillating plates that decrease friction forces in the direction of flow and reduce energy input

- Pneumatic or hydraulic-driven piston actuators

- Motor-driven actuators

Warranty

All Diamondback Technology hoppers are covered by a warranty of nine months or longer, contingent on material flow property testing.

Oscillating Plate Hopper Case History: Spice Company

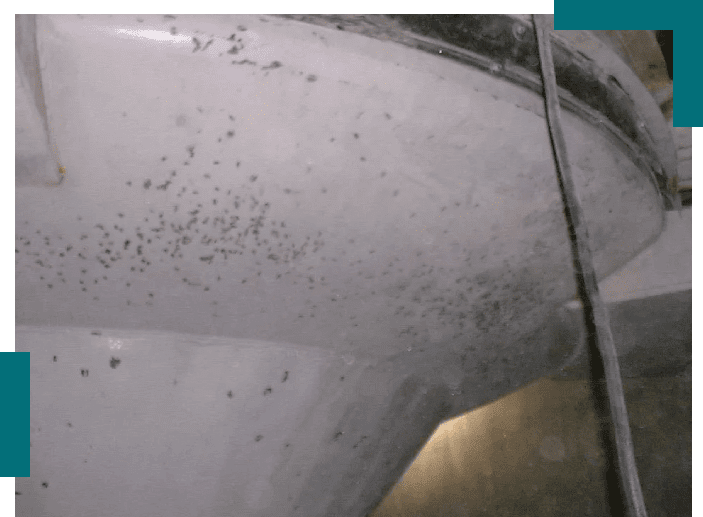

A spice company faced challenges with discharging spent vanilla beans, a byproduct of their vanilla extract production. The beans, softened by alcohol, proved sticky and hard to discharge, with the issue escalating after a few hours of rest. Testing revealed pressure sensitivity in bulk strength, leading to arching in conical hoppers.

Traditional methods like vibration, exacerbated the problem. To address this, we proposed an Arch-Breaking Diamondback Hopper, enhanced with oscillating plates for optimal discharge. Retrofitting their existing hopper with this solution, activated by pneumatic cylinders, resolved the issue effectively.