Diamondback Hopper

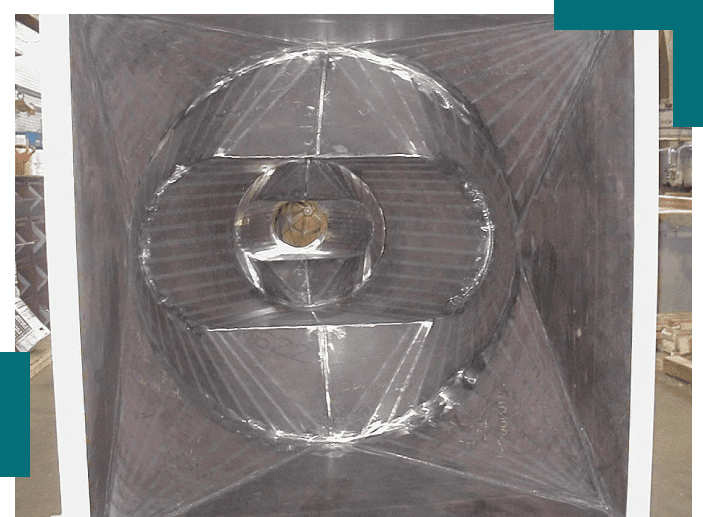

The Diamondback Hopper uses patented one-dimensional convergence dynamics to ensure smooth material flow without the need for moving parts. It eliminates issues like arching, ratholing, flooding, and erratic flow, while also enhancing process flow rates.

Standard Diamondback Hoppers

These hoppers feature innovative one-dimensional convergence dynamics that prevent arching and ratholing. They often replace the need for additional equipment such as vibrators, air cannons, and expensive mass-flow screw feeders. This results in uniform mass flow without maintenance, leading to increased production rates and minimized downtime.

Milling Hopper Case History: Cereal Producer

A Californian milling company faced challenges with stable minds ratholing and excessive dust during truck loading. To resolve this, they replaced the existing vibrated hopper with three Arch-breaking Diamondback Hoppers equipped with air permeation.

Installation involved careful coordination, including jackhammering and cleaning. Once operational, dust during loading was significantly reduced, and with the air permeation unit, trucks loaded in a fraction of the time. The success was evident in the installation of a second identical bin.

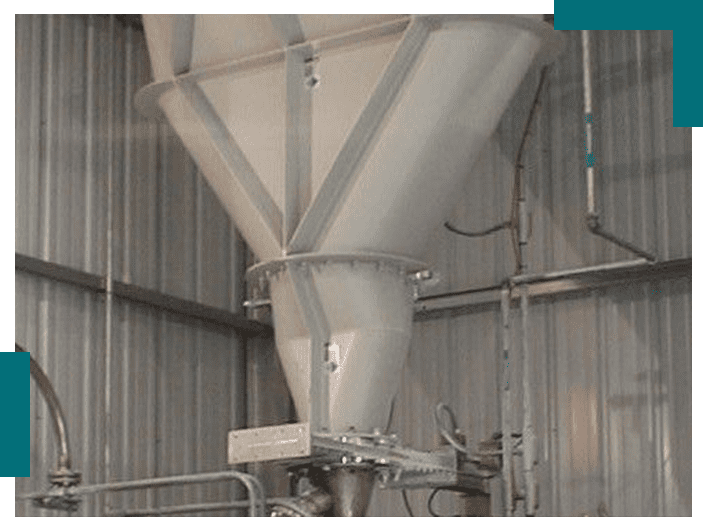

Coal Industry Diamondback Hopper

Converts four-foot diameter outlets to two-foot-diameter outlets.

Retrofit Applications

Multiple Outlet Power Plant Bunkers

Single Outlet Bunkers

Bottom Tunnel Reclaim Hoppers for Coal

Truck Dump Hoppers

Rail Dump Hoppers

Dozer-Loaded Reclaim Points

New Construction for Hangup-Free Operation

Key Features

Constructed with stainless steel for corrosion and wear resistance

Standard pre-engineered designs for various applications

Two-foot-diameter outlets as standard

Transitions to circular bins with a predrilled extra flange

Custom transitions to square or rectangular hoppers at structurally optimal positions

Shipped in sections for on-site bolted assembly

Coal Hopper Case History: Public Utility Company

Faced with the U.S. Government's mandate for cleaner power generation, a Midwestern utility adopted Powder River Basin (PRB) coal from Wyoming. Despite its cleaner-burning nature, PRB coal caused issues in the utility's pyramid-shaped hoppers, necessitating a solution.

After extensive testing, the utility chose to retrofit its existing hoppers with Diamondback Hoppers. The unique racetrack configuration of the Diamondback Hopper optimizes energy conservation, achieving smoother flow compared to traditional conical hoppers.

The modular nature of Diamondback Hoppers allowed seamless retrofitting, accommodating varying shapes and headroom constraints. The result was a multiple-outlet coal bunker operating flawlessly, solving the problem at a fraction of the cost of standard hopper designs.

Pharmaceuticals

An important requirement in the manufacture of tablets and capsule filling is the assay of active ingredients in the lot. Typical steep conical hoppers can cause rejects due to segregation of the batch during discharge. Archbreaking Diamondback hoppers eliminate this problem by delivering the batch contents in a First-In-First-Out (FIFO) flow pattern.