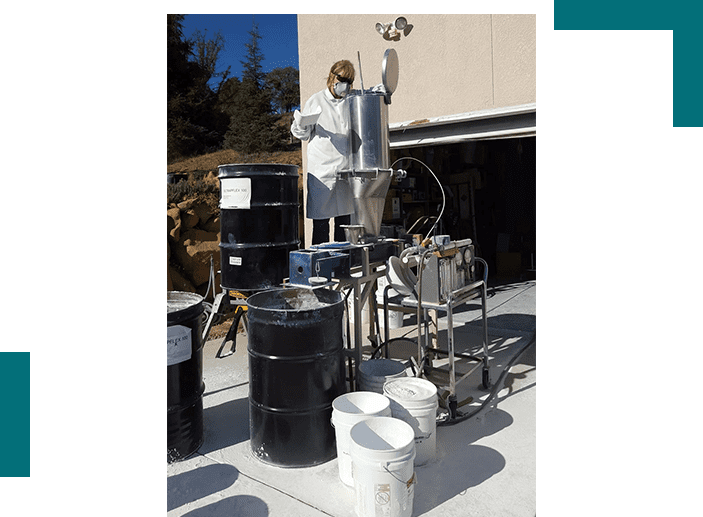

Densifying Screw Feeder

Fine powders can discharge efficiently using a densifying screw feeder. By limiting aeration upstream, venting entrained air, and compacting material while isolating the process from downstream air penetration, a consistently densified product is achievable without additional settling time or erratic flow often associated with fine powders.

The Diamondback Technology densifying screw feeder offers a seamless retrofit solution for existing bins, effectively eradicating issues like flooding, flushing, and irregular flow. It excels at preventing arching and ensures airtight sealing for sack or bag filling, enhancing powder densification by eliminating excess air. The screw feeder also guarantees uniform density for weight hopper applications. Its variable-speed functionality caters to both rapid and controlled feed conditions, making it adept at handling highly cohesive bulk materials with consistent output densities.